In its quest for performance and zero defects, fashion has no choice but to exploit advanced technologies (Big Data, smart factories, 3D technology, Artificial Intelligence, IoT, robots, advanced algorithms and machine learning).

Through these cutting-edge technologies, luxury companies aim to digitize as many of their process components as possible. Their aim is to digitize and integrate the various aspects of their business:

- vertical and horizontal value chains,

- product and service offers,

- business models and customer access.

The new performance model to meet consumer expectations.

Thanks to this modernization, plants are gaining in productivity and speed of execution, particularly on very high-speed lines. This benefits not only consumers, who can be served more quickly, but also employees, who benefit from the improved ergonomics and safety of their jobs.

Of course, by enabling companies to digitize and automate their operations, Industry 4.0 reduces the involvement of human workers in actual production processes and increases both productivity and profits.

The aim is to achieve zero defects, zero waste and constant quality.

Thanks to new technologies, automation and controls can reduce losses:

- networked flow management, from receipt of raw materials to dispatch of finished products,

- automated storage

All this to provide the agility and performance needed to adapt to increasingly complex markets.

New technologies have enabled us to achieve a high level of perfection, and maintaining consistent quality with 2D/3D vision tools and other machine vision applications is now an achievable goal. Respecting quality criteria enhances the value of our creations and ensures that they are not copied.

Automation and controls enable us to reduce waste and increase output, while maintaining the high standards demanded by our customers. This combination of IT, technology, sensors and cameras guarantees quality and constant monitoring.

Today, thanks to Industry 4.0, the luxury industry is able to turn its supply chains into a competitive lever.

A 4.0 supply chain is capable, for example, of reducing transport costs and times, cutting time-to-market and ecological impact, while improving margins.

The data generated by factories is a veritable goldmine, enabling fashion players to improve performance, manage greater product complexity and get closer to consumers.

How can you make the most of productivity levers for a 4.0 factory?

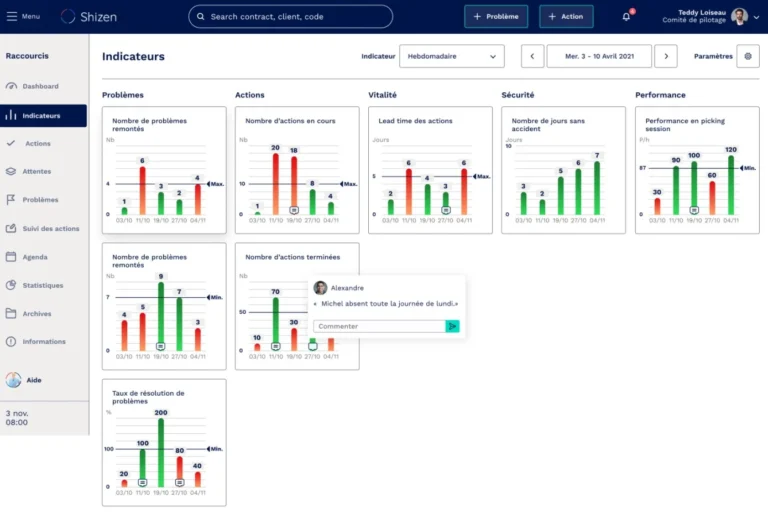

Shizen helps factories move towards 4.0 by offering a digital solution that helps teams manage their performance and push them towards continuous improvement.

The Shizen solution has already met with great success in the luxury sector, and our teams are familiar with the culture of excellence and the demands of the eco-system. Shizen is currently supporting Richemont in their continuous improvement process.

The collaboration between Richemont International Distribution (the Richemont Group’s global distribution center)* and Shizen is part of a project to digitalize logistics operations.

Richemont’s teams were convinced that digital was a way of supporting the teams in managing their activities. Thanks to Shizen, three problems were identified in advance:

the difficulty teams have in reporting problems,

a lack of communication between teams,

a lack of rigor in the routines.

In 6 weeks, here are the results that have been reported:

30 problems reported

30 shares created

4 problem-solving workshops

1 Kaizen project launched

“We chose Shizen because it’s a comprehensive tool and above all because its highly structured approach enabled us to rapidly disseminate best practices in performance animation and Lean management.”

Are you a major player in the luxury goods industry looking to implement a digitalization initiative as part of the creation of a Factory 4.0?

Ask for a demonstration of the Shizen solution.

Conclusion:

Technology is not an end in itself, but a receptacle for fashion know-how, capitalizing on the experience of men and women. Another important notion is that of ecosystems: Industry 4.0 will change the rules of the game by connecting all fashion players. Companies will be able to rethink themselves, and new entrants will emerge. There will be winners and losers. If you don’t reposition yourself, you lose out right from the start.

This industry, which has always used know-how, is also the first to know how to make it evolve. Through Industry 4.0, the creativity and culture of excellence of the luxury industry work in synergy with technology to develop high-quality products that are ever closer to the demands of the sector’s customers.

* Richemont owns a portfolio of internationally renowned Houses, renowned for their heritage, expertise and creativity. The Group operates in four areas: ‘Jewellery Maisons’, comprising Buccellati, Cartier and Van Cleef & Arpels; ‘Specialist Watchmakers’, comprising A. Lange & Söhne, Baume & Mercier, IWC Schaffhausen, Jaeger-LeCoultre, Panerai, Piaget, Roger Dubuis and Vacheron Constantin; ‘Online Distributors’, comprising Watchfinder & Co, NET-A-PORTER, MR PORTER, YOOX, THE OUTNET and OFS; and ‘Other’, the majority of which are Fashion & Accessories houses, including Alaïa, AZ Factory, Chloé, dunhill, Montblanc, Peter Millar, Purdey and Serapian.